Click to Call

Click to Call

Metkorp Equipments Pvt. Ltd is a Leading Hardness Analysis Software Service Provider company in Ajmer. We offering Hardness Analysis Software at Best Price in Ajmer. The offered Hardness Analysis Software in Ajmer is valued by our patrons for their quality. The complete range of Hardness Analysis Software is having export quality supplying in Ajmer. The offered Hardness Analysis Software in Ajmer, is checked on various parameters by our quality controllers.

Hardness Analysis Software Service Provider in Ajmer, Hardness Analysis Software Supplier in Ajmer, Hardness Analysis Software in Ajmer, Hardness Analysis Software at best price in Ajmer.

FEATURES

| Used In | :- | • Overhead cams • Crank shafts • Gear boxes • Constant velocity joints |

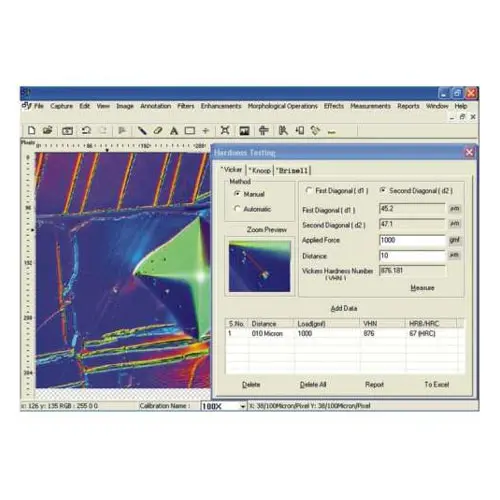

| Methods Used | :- | • Brinell hardness • Vickers hardness • Knoop hardness |

The Hardness Analysis Software that we offer has no other alternative available in the market when it comes to reliability and high efficacy. The Hardness Analysis Software is used in varied applications and therefore is demanded all across the globe. Our team of well experienced professionals is engaged in developing Hardness Analysis Software.

SPECIFICATION

Micro hardness testing applied in areas including metallography, precision mechanics, electroplating, material testing and material science. In order to determine micro hardness, different shaped indents are pressed into flat material samples with a defined force. Three methods available are :

BRINELL HARDNESS

In Brinell hardness test, an indentation hardness test in which a hardmetal ball is forced into the surface of a test piece, mean diameter if the indentation is left on the surface after removal of the test force is measured. The Brinell hardness HBW is obtained by software.

VICKERS HARDNESS

The Vickers hardness test, measure length of the diagonals of indentation left in the surface in which a Square-based diamond pyramid, having an angle of 136 degree between the apposite faces at the vertex, is forced. The Vickers hardness is obtained by dividing the test force by the area of the sloping faces of the indentation. The Vickers hardness HV is displayed by software.

KNOOP HARDNESS

The knoop hardness test is an indentation hardness test in which a rhombic-based diamond pyramid, having an included longitudinal edge angle of 172.5 degree and an included transverse edge angle of 130 degree, is forced into the surface of a test piece. The length of the long diagonal of the indentation left in the surface after removal of the test force. The Knoop hardness HK is calculated by software.

One Stop Solution for Latest Metallography Equipment which You Required for Your Laboratry.