Click to Call

Click to Call

Metkorp Equipments Pvt. Ltd is a Leading Welding Analysis Inspection System manufacturing company in Indore. We offering Welding Analysis Inspection System at Best Price in Indore. The offered Welding Analysis Inspection System in Indore is valued by our patrons for their quality. The complete range of Welding Analysis Inspection System is having export quality supplying in Indore which is manufactured by using modern techniques under the observation of skilled professionals. The offered Welding Analysis Inspection System in Indore, is checked on various parameters by our quality controllers.

Welding Analysis Inspection System Manufacturers, Supplier in Indore, Welding Analysis Inspection System in Indore, Welding Analysis Inspection System at best price in Indore.

FEATURES

• Objectives range of zoom magnification: 0.7x-5x

• 10x Eyepieces field is extra wide and clear.

• The observation eyepieces tubes are inclined at 45 degree & Can be rotated 360 degree, The adjustment range of interpupillary distance: 53-75mm,

• Diopter adjustment ring on ocular tube

• All lenses are imported & antifungal treated.

• Provision for camera port at top of the microscope.

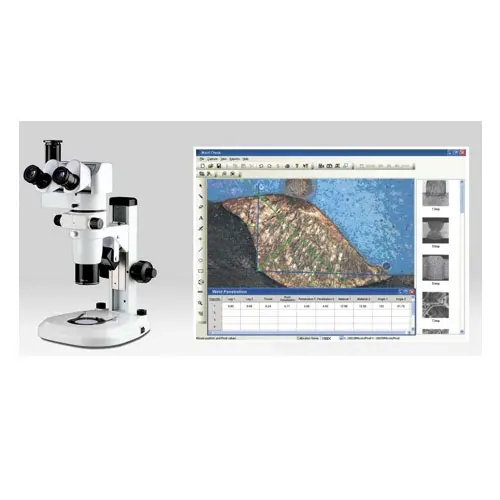

Welding Analysis Inspection Systems Manufacturers/Suppliers in Indore. A new and improved model of zoom stereoscopic microscope which can magnify micro object continuously and accurately to show 3 dimensional image for observation studies in health, Medical, Forestry & Zoology department as well as for repair of tiny precision spare parts of electronic and Jewellery. Magnification ranges from 7x to 50x.

A latest three dimensional zoom stereoscopic microscope for observation studies in health, Medical, Forestry & Zoology department is provide with special high eye point wide field eye pieces 10x, Para focal zoom objectives of 0.75x to 5x providing Continuous variable depending upon the eye pieces and supplementary lens used, Having well designed pole stand, Having extension pillar, 360 degree revolving zoom Trinocular head and 6 volts 21 watts incident spot light illuminator with light control transformer and built in base illuminator 6v-20w halogen lamp, Packed in wooden box with lock and key.

TECHNICAL SPECIFICATIONS

EYEPIECE

Wide field Eyepieces 10X (Paired) FOV 22mm

OBJECTIVES

Zoom 0.7X to 5x with magnification ratio of 6:1

MECHANICAL BODY

• Lateral zoom control movement.

• Reflected and transmitted light system with 12V-10W halogen tungsten lamp.

• The system regulated with transformer has intensity control knob.

• On/off switch provides flexibility to use either both light or any of them.

• Clip for holding specimen.

• Base size is 260mm X 290mm.

MAGNIFICATION RANGE

7X - 50X

WORKING DISTANCE

98mm

WELD CHECK SOFTWARE

Weld Check software is a powerful easy-to-use tool that enhances your ability to quickly and efficiently handle your most critical welding measurement and documentation software needs. Your workflow and productivity are greatly improved. Weld Check has been designed with your welding cross-section measurement needs in mind. Weld Checks measurement module allows you to quickly measure such items as your fillet welds, throat, leg lengths and penetration.

Use Weld Check Measurement Tolerance indicator to improve performance by having the software automatically tell you if a measurement is out of the tolerance range.

The following report concerns the analysis of a fillet weld, a weld of approximately triangular cross section joining two surfaces at approximately right angles to each other. Important measurements made by the distance from the root if the fillet to the center of the face (or throat), the distance from the root of the joint to the junction between the exposed surface of the weld and the base metal (or leg), the angles and the root penetration. Measurements that could have been done with the same ease or similar sample are among others : depth of HAZ (heat affected zone), area of HAZ, joint penetration, phase counting, etc.

The measurements remain unaffected if the image is zoomed for better accuracy. T he magnifier tool is also available which can be switched on any part of image. The tool zooms only the region surrounding the cursor allowing to increase the drawing precision while still seeing the whole sample.

Image analysis system can measure a sequence of specific characteristics or welded parts. The system brings the good tool with the good color when its the time for the operator to use it.

MEASUREMENTS

• Calibration.

• Leg 1 and Leg 2 measurements, throat measurement and Penetration measurements

• Can measure length, area, angle, diameter, radius, circumference in addition to weld penetration measurement

• Can find mid-points, perpendiculars to lines, angle between lines

• Ability to store drawings as a template for future use, thus ensuring maximum

• Repeatability

• Automatic measurements based on stored template, eliminating the need for manual measurements

• Automatic profile measurements

• Ability to create a master template for measurements for each type of component

• Ability to set expected value as well as tolerances at individual work level or at a master template level

• Automatic edge detection

• Programmable (Automatic) measurement

• Ability to stitch multiple reports together into a single report at component level if there are multiple welding on a component

• Integrated online Help

REPORT

• Reports in Excel or PDF format

• Report will have the measurement data as well as the image with drawings

• Report on weld machine performance (Total, Pass, Fail)

• Historical data analysis with performance graphs and deviation analysis reports

One Stop Solution for Latest Metallography Equipment which You Required for Your Laboratry.