Click to Call

Click to Call

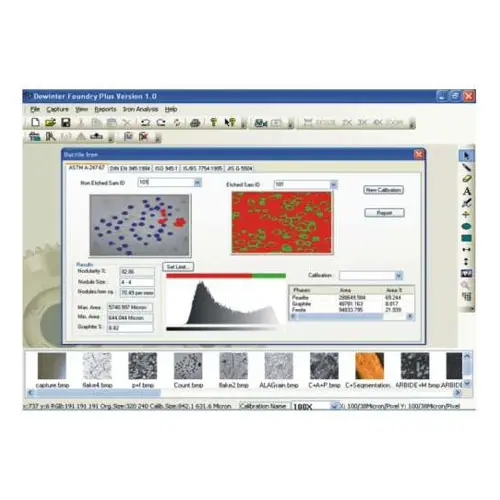

Metkorp Equipments Pvt. Ltd is a Leading Metallurgical Image Analysis Software Service Provider company in Montenegro. We offering Metallurgical Image Analysis Software at Best Price in Montenegro. The offered Metallurgical Image Analysis Software in Montenegro is valued by our patrons for their quality. The complete range of Metallurgical Image Analysis Software is having export quality supplying in Montenegro. The offered Metallurgical Image Analysis Software in Montenegro, is checked on various parameters by our quality controllers.

DETAIL FEATURES OF METALLURGYPLUS

Metallurgical Image Analysis Software Service Provider in Montenegro, Metallurgical Image Analysis Software Supplier in Montenegro, Metallurgical Image Analysis Software in Montenegro, Metallurgical Image Analysis Software at best price in Montenegro. This software can be used in Steel plants, Metal forging industry, Oil & gas industry ,Material Science, Mineralogy - metal and metal strength analysis Cement (Klincker) quality control and where ever Metallurgical microscope are used in .This Package is very useful Educational Institutions and ALL MATERIAL SCIENCE TECHNOCRATS AND

METALLURGISTS.

It has two main toolbars

1) Measurement Tools

2) Metallography Tools

1. Measurement Tools.

(A).Calibration:- This tools is for calibrating through calibration scale. This is done once while the system is integrated with Camera/Microscope/Adapter and the Software. And the Calibration remain as Standards for any future Capture and Study.

(B).Length:- This is used for measuring length .It can measure any given length found in the image with respect to any findings or portions thereof. It calculates according to your selected calibrated scale name, choosen from the list of predetermined Magnifcation.

(C).Angle:- This is used for measuring angles of three selected point of the captured image.

(D).Perimeter:- This is used for measuring perimeter of irregular shapes

(E).Width:- This is used for measuring width .It will give Minor Width, Major Width and

Average Width too.

(F).Radius:- This is used for measuring three points radius.

(G).Area:- This is used for measuring area with respect to Manual selection of a portion, Square, Rectangle, Oval and Circle.

(H).Color:- This enables to select a Contrast Color for easy visualization and draw.

(I).Counting:- The Material Pro 3.0 enables automatic counting of particles. It has three intensity range for counting such as manual , automatic and bright objects determination method. In the process total count is derived, Max dia, Minimum Dia, Max Area, Min. Area and Its percentage etc., based on the Area Range in different color it can be identified , Each Grain Particle can be distinguished and numbered automatically, Label color can also be changed, . It is used to measure and density parameters for the image objects (particles powders, inclusions, grains, etc.)

2.Metallography Tools.

(A).Grain Size:- As per American Standard of Testing Materials(ASTM) Grain Measurement and Number can be arrived at with direct tabulation method on two methods.

1. Manual and Interception . In manual you can select with mouse. It will measure Intercept, Diameter , Grain No., Avg, Grain Area(mm).and measures to ASTM E 112 method. 2. In Interception method it is automatic. It will measure Mean Intercept, Diameter, Grain No., Avg, Grain Area in (mm), Avg. Grain Area in (mm).

(B).Phase:- ASTM E 566 1245

This is used to estimate the area percentage of different phases composition of material. Phase Analysis. Thresholding can be done by different colors. Number of Phases can be drawn. Preview can be seen. It will calculate Area% and Area of selected Phase in different colors. Single Phase can be done by simply clicking on particular portion and it can be reset or deleted.

It allows user to acquire, process , and analyse the images of the polished sections when it is necessary to estimate the area percentage of different phases. If the image is color or b/w (depending on the image)the program starts its processing. The phases for (e.g different minerals, inclusions in the metals, etc.) are threshold. For phase thresholding the B/W or Color manual thresholding method is used. If you are not satisfied with their thresholding there is an ability to adjust it by moving the graphical sliders.

(C).Decarbization:- ASTM E 1077

This is used for Decarbization . It has two method Manual and Automatic. In manual method you can simply mark two different portion then it will calculate the decarb level In automatic you have to simply move the slider and click on Decarb it will calculate Max, Min and Average of decarb level.

(E).Coating Thickness:- ASTM B 487

It has two options Manualy and Automatic .In manually simply mark your Area for calculating then it will calculate. In Automatic simply mark your portion with the mouse it will be appeared in rectangular shape then click on calculate.It will give results in Min Length, Max length, Average length, Min height ,Max height and Average height.

(F).Nodularity:- ASTM A 247

This is used for Nodules analysis. It has three intensity range for counting Manual by selecting area, Automatic dark objects, Automatic bright objects. It will Count in Total Count, Max Dia , Min Dia, Max Area, Min Area, Percentage. It will give results in Total Objects, Nodule count, Nodularity %, Nodules /mm sq , Max Dia , Min Dia, Max Area , Min Area.

(G).Porosity:- ASTM 276

This is used for Porosity Analysis. It has three intensity range for counting Manual by selecting area, Automatic dark objects, Automatic bright objects. It will Count in Total Count, Max Dia, Min Dia, Max Area, Min Area, Percentage. It can be Measured on selected Phase also by simple clicking on your sample images. It will give Results in Field Name, No. of count, Area %, Dia Average, Area Average.

H).Inclusion:- ASTM E 454 – E 1245

Non-Metalic Inclusion rating can be done by ASTM & DIN standards. It will give in Min, Max , Length, Width , Ap. Ratio., Type ,Severity level. It will give results for Type in A Thin, A Thick, B Thin, B Thick, C Thin, C Thick, D Thin, D Thick. For Severity level it starts from .5 , 1, 1.5, 2, 2.5 to 5.Results in %.

I).Particle Measurement

This is used for measuring particles by simple clicking on it . It has three intensity range for counting , Manual by selecting area, Automatic dark objects, Automatic bright objects. Labels in numbers ,Color of label can be changed. It will give results in Sr. No.,Length, Width , Area and Ap. Ratio.

(J).Density

This is used for measuring density in Black & White images. It will give results in %.It can be done by simply dragging the mouse on the image as rectangular shape.

(K).Filters

It has various filter for improving image quality. It has Solarize, Emboss, Bright, Sharpness, Smooth, Diffuse, and Contrast. It can be done simply moving slider.

(L).Invert

Image can be changed in Invert and can be saved with new name.

(M).Annotation

It has various options like you can write text on image, We can mark with arrow, We can mark with pointer, We can draw square and rectangle on image. We can change Line color, text color, Font color ,size, Font name, Bold, Italic ,Underline. These all can be saved with new file name. It can be refresh if you have made any mistake.

(N).Back Ground Removal

It is used for removing background color, that is used in Phase Analysis. It is used when

an image is not cleared.

(O).Amalgamation

This is for merging two images.

SOME MORE FEATURES FROM MAIN MENU ARE :-

(A).Save & Save As

This is used for images with different names.

(B).Report Preview

This is used for giving details reports like Name, Evaluation Date, Sample ID No., Application, Operator, Microscope Objective. A fter filling de tails, You can see reports in MS-Word and MS-Excel formats ,It will generate reports with image ,data, various other related information and all details results, and also with Histogram with different colors. Reports can be generated with the company's logos and its name and address. Now you can see report in Excel with two images Original Image and Effective Image. Now report is in best format.

(C).Zoom

Image can be enlarged .

(D).Inclusion DIN

This is used for measuring Inclusion Rating as Per Din standards (50602). It will show

Graph, Min & Max, Length, Width, Aspect ratio, Polished Area in Six No., and with SS, OA, OS, OG.

(E).DIN PER

This tool is used for Analysis of Ferrite, Pearlite, Graphite, Carbide and more. We will get result in Min Value, Max Value, Area%.

(F).Hardness Testing

Micro-Hardness analysis can also be done. We can obtain knob, Vickers or Brinell. Hardness measurement from indentation image. This will give result of Hardness testing in Vickers and Brinnel values like d0, d1, Hv.

(G).Gallery

In this features you can make album of your captured images for further use. You can add new images into gallery, Delete old one, You can see with zoom view and you can see the details of the images.

(H).Company Name

We can change the name of company like Address, City, State, Pin, Email Phone, Fax, URL and logo.

(I).Delete Calibration

We can also delete unwanted calibration from combo box.

(A).Open Image

Now we can open image in .bmp and .jpeg, format.

(B).Open Image & Convert

Now we can open image in .tiff , .pcx , .rle , and .awd then Convert it into .bmp and .jpeg then use for analysis.

(C).Show Capture

We can directly capture images through the software without going outside the software .It has various features. You have to installed only frame grabber card driver We can easily capture images into the computer. We can capture images in .bmp format. It has more feature like :-

I. Close Capture

II. Load Palette

III. Set Capture File As *.avi etc.

IV. Allocate File Space

V. Save Captured Video As

VI. Save Palette

VII. Save Single Frame As .bmp

(D).Image

1.Modify or Comparison

We can call it Cut -Copy and Paste .We can simply drag the image from the list box In this features we can copy, cut, paste, a particular portion of image later on we can paste it on the image and can be moved any where on the image .It can be fixed on the image. Further the modified image can be saved with new file name. It has feature like Undo, Redo, Clear, Update layers. We can add comments on the images with different colors. We can move our comments also by simple clicking mouse on particular portion.

2.Gray Scale

We can change image into gray scale by simple click .

3.Resize Picture

We can increase image size from 100% to 800% assume value in 1 to 8 .We can decrease images size from 100% to 10% assume value in 1 to 10.

(E).Options

It has various options for capturing cards.

I. Audio Format

II. Format

III. Source

I V . Display

V . Compression

V I . Preview

V II. Overlay

V III. Card Details.

(F).Capture

This option is also for capturing.

I. Single Frame

II. Frames

III. Video

I V . Palette

1.MEASUREMENT TOOLS.

TWO NEW FEATURES IN THIS ARE

(A). Flakes

It will give result in Max Length.

(B).Draw Free Circle

This circle can be drawn with different colors on the image.This is useful when we want to differentiate a particular particle when they are attached .Then they can be counted alone. This new image can be saved with different name.

2.METALLOGRAPHY TOOLS.

(A).Phase on Rectangular Area

In this we can do Phase analysis on a rectangular area. We can draw different Phase on that area through the help of thresholding .We can do simple phase by clicking on particular Phase .It will give results. We can also see the preview of all phases. This Phase analysis is Histogram based.

(B).Amalgamation

Now we can merge three different images into one image, further we can save it with different name.

Note- Specifications are subject to change due to our continuous R&D programme

One Stop Solution for Latest Metallography Equipment which You Required for Your Laboratry.